Anyway, tonight I went to the barn despite the weather being terrible and I was determined to do something on the VDP even just to get some sort of enthusiam back up for the job. It was -2 degrees inside the barn and to warm up on arrival I got the footpump out to inflate the front RHS tyre. I found myself looking at the vacumn tank that lives under the front wing. It is hardly a vital part of the main job - ie rebuilding the body - but I figured it could be refurbished and it would give me a chance to check for any corrosion behind it on the inner wing.

plastic reservoir held onto body with steel rings

2 x nuts removed from studs with 7/16" socket

unusual set up on other side. nuts can be screwed back along threads but apparently not other way

The front nuts came of fine but the rear ones were rusted and I didn't want to shear them so I dug out the sandblaster as it is a great way of cleaning up rusted threads but the downsides with blasting have been detailed before here in a previous post. For some reason I could not get the sandblaster to function. It seemed to be under great pressure with no grit coming out the nozzle but air escaping from every other joint. After an hour so of trying to resolve the problem and only getting a small bit of rusted thread cleaned up I called it a day as it was 11pm and I was freezing and hungry but its a start I suppose.

small amount of rusted thread cleaned up with sandblaster

screw clip loosened inside engine bay. metal pipe leads into rubber hose integral with tank assy

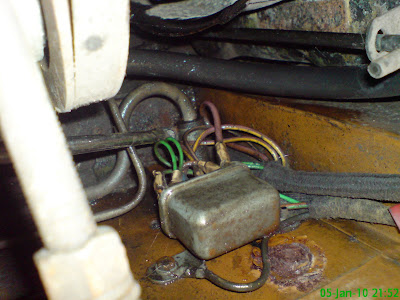

Before bed I examined the Parts List to see exactly how the vacumn reservoir is connected to the inner wing. Turns out the small nuts tighten against an internally threaded barrel which has a large hex head accessible from inside he engine bay. You can see the upper one in the pic above. It's the rusty looking thing between the wire and the time stamp. It might therefore be possible to simply unscrew this without worrying about the rust on the thread on the other side. I really need some new grit for the blaster and I suspect the sub zero temp last night may have been to blame for the thing not working. Might be better to just use WD40 on the other side.

No comments:

Post a Comment